Still a concept car, the 1,825hp Bolide is based on the Chiron featuring a modified version of the iconic W16 engine with a minimal body for maximum downforce. Although Bugatti has not said if the car would go into series production, chances are it would if its select clientele clamour for it.

The Bolide lays claim to being "the most extreme, uncompromising, fastest and lightest vehicle concept in the company’s recent history ".

It has an unprecedented weight-to-power ratio of 0.67 kg per PS. This is made possible by the combination of the W16 engine with 1,825hp and a vehicle weight of just 1,240kg.

The Bolide achieves figures that are almost on par with Formula 1 while its top speed is well above 500kph – without compromising optimum handling and maximum agility. The Bolide takes 3 .07.1 minutes to complete a lap of Le Mans and 5 .23.1 minutes to get around the Nordschleife and thus promises to offer the ultimate Bugatti performance kick.

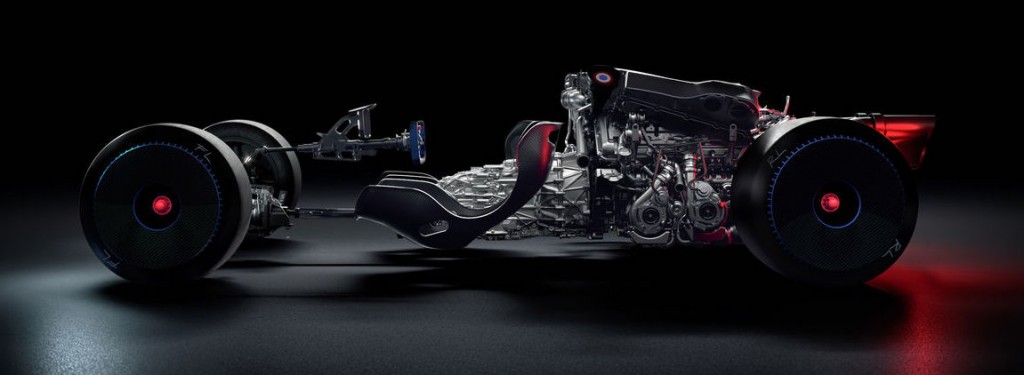

The 8.0-litre W16-cylinder engine with 1,825hp and 1,850Nm of torque is at its heart. Bugatti has designed the drive specifically for use on the racetrack and has optimised the engine and gearbox in particular for higher engine speeds.

Among other things, this includes dethrottling the intake and exhaust system to achieve an even faster, more spontaneous, and extreme response characteristic. The four newly developed turbochargers are fitted with optimised blades in order to build up more boost pressure and power at higher engine speeds.

In order to achieve optimum lubrication even under extremely high centrifugal forces, the oil circuit, oil pressure, check valves, baffles, oil tanks, oil reservoirs, and pump design of the dry sump lubrication have been optimised.

The weight of the drive system is also significantly reduced at the same time.

Instead of water-to-air intercooling, the Bugatti Bolide has air-to-air intercooling with water pre-cooling for optimal performance on the racetrack. The inflow takes place from the front via one internal and one external air duct on each side of the vehicle.

The two water coolers, which are arranged in front of the front axle, provide a more effective radiator system in terms of flow than is customary even in Formula 1. Three air-cooled oil coolers for engine, transmission, and differential with water pre-cooling reduce the temperature even on dynamically demanding race laps.

Newly developed and hybrid carbon titanium turbofan radial compressors ventilate and cool the high-performance racing brake system.

With an overall height of only 995mm, the Bugatti Bolide is exactly the same height as the historic Bugatti Type 35, depending on the steering wheel and truncated windscreen, and about 300mm flatter than the Chiron.

The wheelbase is 2.75 metres and the width 1.99 metres. Like in an LMP1 racing car, the occupants fold up the doors that are hinged at the front at an angle, sit on a sill that is only 70mm wide, as in a Type 35, and then position their feet in the interior. Thanks to a side wall that is about 150mm, lower than that of the Type 35, the procedure is quick and easy – for drivers up to a body height of 2 metres.

In order to achieve a dry weight of 1,240kg, all the stops have been pulled out with regard to the materials and production processes used, both in terms of what is currently feasible and what will be possible in the future.

All the screw and fastening elements of the Bolide are made completely out of titanium.

In addition, hollow, thin-walled functional components made of an aerospace titanium alloy are used in many places. These originate from a 3D printer and are extremely thin with wall thicknesses of up to 0.5mm.

However, they are still very stable with a tensile strength of 1,250 newtons per square millimetre. Hybrid components, such as the 0.5- metre-long auxiliary drive shaft, combine wound high-strength and ultra-stiff carbon fibres with 3D-printed titanium end fittings and can withstand a continuous operating temperature of up to 260 degrees Celsius.

In this example, this reduces the weight by around half to 1.5 kg and, due to the reduction of the rotating masses, increases the revving ability of the engine at the same time. The forces acting on the front and rear wings are transferred by ultralight but very solid titanium elements. They weigh a mere 600 grams at the front and an astounding 325 grams at the rear.

A worldwide innovation is the morphable outer skin of the intake scoop on the roof, which provides active airflow optimisation. If the vehicle is driven at a slow speed, the surface of the scoop remains smooth. In contrast, a field of bubbles bulges out when driven at fast speeds.

This reduces the aerodynamic drag of the scoop by 10 percent and ensures a 17 percent reduction in lift forces. In addition, the flow onto the rear wing is optimised. At 320 km/h, the downforce is at 1,800kg at the rear wing and 800kg at the front wing.

As in Formula 1, the Bolide decelerates with racing brakes with ceramic discs and coatings. The brake callipers weigh only 2.4kg each. The front forged magnesium rims with central lock weigh 7.4kg, while the ones at the rear weigh 8.4kg – with a very wide tyre size of 340mm on the front axle and 400mm on the rear axle (Chiron: 285 mm at the front and 355 mm at the rear). A compressed-air-driven jack system with four rams makes tyre changing easier, a quick refuelling system allows pressure refuelling.

Among other things, a push rod kinematics system with horizontal dampers ensures precise handling. The oil reservoirs are arranged inside the dampers, which improves aerodynamics.

Weighing only 100 grams, the push-rods are designed as a thin-walled and flow-optimised titanium lightweight construction with a buckling load of 3.5 tonnes, which corresponds to a dry weight of nearly two Chirons. The welded control arms made of aerospace-grade stainless steel have a tensile strength of 1,200 newtons per square millimetre and are also designed as wing profiles.

The Bugatti team developed a light monocoque made of carbon around the drive. The integral front end flanged to it is also made of high-strength carbon fibres, as are the fully aerodynamically effective underbody and the monocoque itself.

The single-fibre tensile strength of the fibres used is 6,750 newtons per square millimetre, the single-fibre stiffness is 350,000 newtons per square millimetre. These represent figures that are only reached in the aerospace industry. The rear frame, designed as a welded steel assembly, offers a maximum tensile strength of 1,200 newtons per square millimetre, despite a wall thickness of only 1 millimetre – this is made possible by the use of high-strength stainless steel, which is otherwise only used in aviation.

Safety is ensured with safety equipment designed in accordance with FIA regulations. These include HANS device compatibility, an automatic fire extinguishing system, a towing device, pressure refuelling with fuel bladder, central locks for the wheels, lightweight polycarbonate windows, and a six-point harness system.

The monocoque side floors with integrated carbon coolant pipes are simultaneously designed as side impact structures and structural reinforcement of the monocoque. The driver can see all the relevant data on a motorsport display. For an optimum sitting position, both the pedals and the passenger footrest can be moved by 150mm.

The Bolide look invokes the so-called X-planes of aviation history and shows a clear X signature from every angle. It is indirectly reminiscent of the Bell X-1 jet aircraft which was flown by Captain Charles “Chuck” Yeager 1947, the first person to break the sound barrier at Mach 1.06.

The Bolide “X-periment” has the shape of an aerodynamically optimised, uncompromising racing car and offers ultra-sporty, superlative performance – with no hint of luxury.

“All of Bugatti’s expertise has been condensed into the Bugatti Bolide. It is therefore an innovative information source for future technologies. The Bolide is thus more than just an intellectual exercise," said Stefan Ellrott, member of the Board of Management of Bugatti and Head of Technical Development.