INGOLSTADT: Audi AG is consistently rolling out artificial intelligence (AI) in production and logistics.

The premium automaker is scaling up its own cloud platform for production and introducing new AI use cases and technologies for large-scale series production.

“With our AI and digitalisation roadmap, we are transforming our plants into smart factories where AI acts as a partner, providing our employees with tailored support. The first AI-controlled robots are taking over tasks that are ergonomically strenuous, and chatbots are providing additional relief,” explains Audi AG member of the board of management for production and logistics Gerd Walker.

“We are bringing together Audi’s decades of production expertise, our own innovative strength, and the expertise of strong partners such as the Innovation Park Artificial Intelligence (IPAI) in Heilbronn.”

Audi AG is putting the Edge Cloud 4 Production (EC4P) into operation across its production environment.

In doing so, the company is setting the next benchmark in fully networked factory automation and at the same time laying the foundation for the widespread use of AI in production.

EC4P makes it possible to combine conventional automation technology with flexibility and computing power from the cloud.

This allows Audi to simplify processes, reduce the amount of hardware required on site, and introduce new functions more quickly.

That makes processes more stable, reduces maintenance costs, and increases IT security.

In vehicle assembly at German plants, for example, worker guidance is increasingly being controlled centrally from the cloud: employees on the production line receive information such as vehicles' specifications or regional versions from a central source in real time.

The move to the cloud has already eliminated the need for more than 1,000 industrial PCs.

In the body shop for the A5 and A6 series in Neckarsulm, Germany, EC4P is now being used in a highly automated production environment for large-scale series production for the first time.

Virtual programmable logic controllers (vPLC) are replacing local hardware controllers on the production lines.

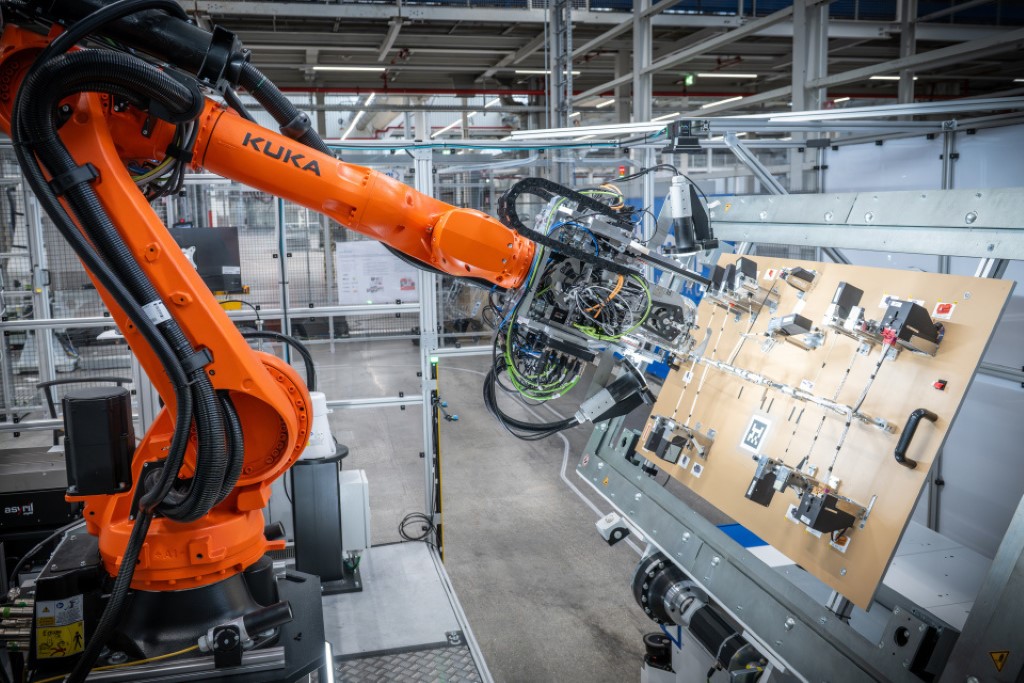

Industrial devices, including around 100 robots, work together via the EC4P with millisecond precision.

The EC4P meets the highest requirements for a smooth production process, enabling several hundred vehicle bodies to be manufactured every day in three shifts – a benchmark that is unique in the industry to date.

The Weld Splatter Detection (WSD) system will also run on the EC4P in the future, enabling even greater flexibility and scalability.

At Audi’s Neckarsulm site, WSD detects weld splatter on the underbody of a car body and marks it with light.

Thanks to a recent upgrade, a robot arm has taken over grinding them down – a physically demanding job.

The Volkswagen Group's first AI-supported weld spatter detection system will soon go into series production at six plants in Ingolstadt.