MUNICH: BMW Group will introduce flax-based natural fibre composites into forthcoming series-production models after confirming the material meets full-vehicle homologation standards, including the highly loaded roof structure.

The components, developed with Swiss clean-tech firm Bcomp, cut production-phase carbon-dioxide-equivalent emissions by around 40 % compared with carbon-fibre-reinforced plastic, and offer additional end-of-life recycling advantages.

BMW i Ventures holds a stake in Bcomp and has co-funded several years of materials research to bring the technology to market.

Lightweight construction has long been central to BMW’s product strategy; substituting renewable flax fibres for energy-intensive carbon or glass fibres advances that goal while aligning with the company’s 2030 climate-neutrality roadmap.

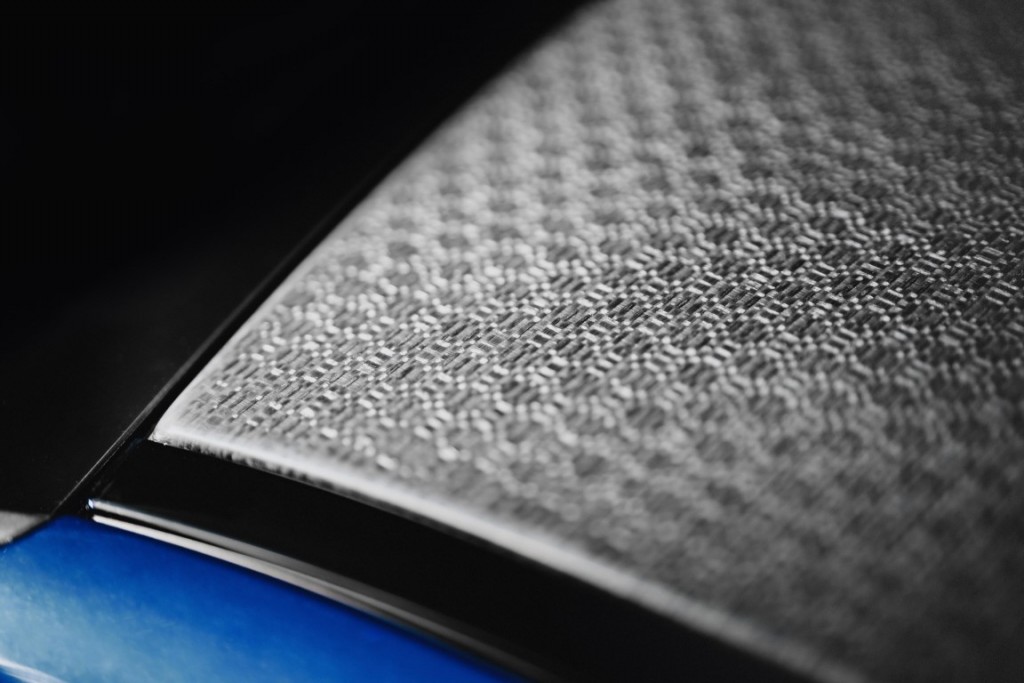

Laboratory and vehicle tests showed the bio-based weave delivers comparable stiffness and crash performance to traditional composites, making it suitable for both visible exterior panels and interior trim.

Motorsport provided the development platform.

Natural-fibre reinforcement first appeared on BMW M Motorsport’s Formula E cars in 2019, then replaced several CFRP pieces on the BMW M4 DTM and M4 GT4.

Since 2022 Bcomp has been an official technical partner for the GT4 programme, and this weekend’s 24-hour race at the Nürburgring will field cars fitted with the latest composite roof, splitter and aerodynamic inserts.

BMW M GmbH chief executive Franciscus van Meel said the material “reduces CO2e in manufacturing while proving our ‘born on the racetrack, made for the streets’ philosophy”.

Series-production roll-out will begin with selected high-performance models; engineers are finalising tooling for future M cars and exploring wider use across core platforms.

The company notes that flax fibres are cultivated in Europe, require minimal irrigation or pesticide input, and are processed at lower temperatures than carbon fibre, further improving life-cycle metrics.