MUNICH: BMW Group Plant Steyr has began series production of the e-motor for the Neue Klasse.

“Today, we are laying the foundations for the future of the BMW Group,” explained BMW AG's member of the board of management (responsible for production) Milan Nedeljković.

“As the first production site for the Gen6 electric motor, Plant Steyr is central to the Neue Klasse and the continued development of our global production network.”

The electric motor for the sixth generation of BMW eDrive (Gen6) is the first fully-electric drivetrain to be produced at the Steyr location in Austria.

From there, it will be shipped throughout the production network, providing the drivetrain for the Neue Klasse.

“Three years ago, we announced that we would build this electric motor in Steyr. Today, we are proud to deliver it,” said BMW AG's SVP of engine production Klaus von Moltke.

“What we are launching here today is more than just a production ramp-up. It is a firm commitment to Europe, to technology and to the future.”

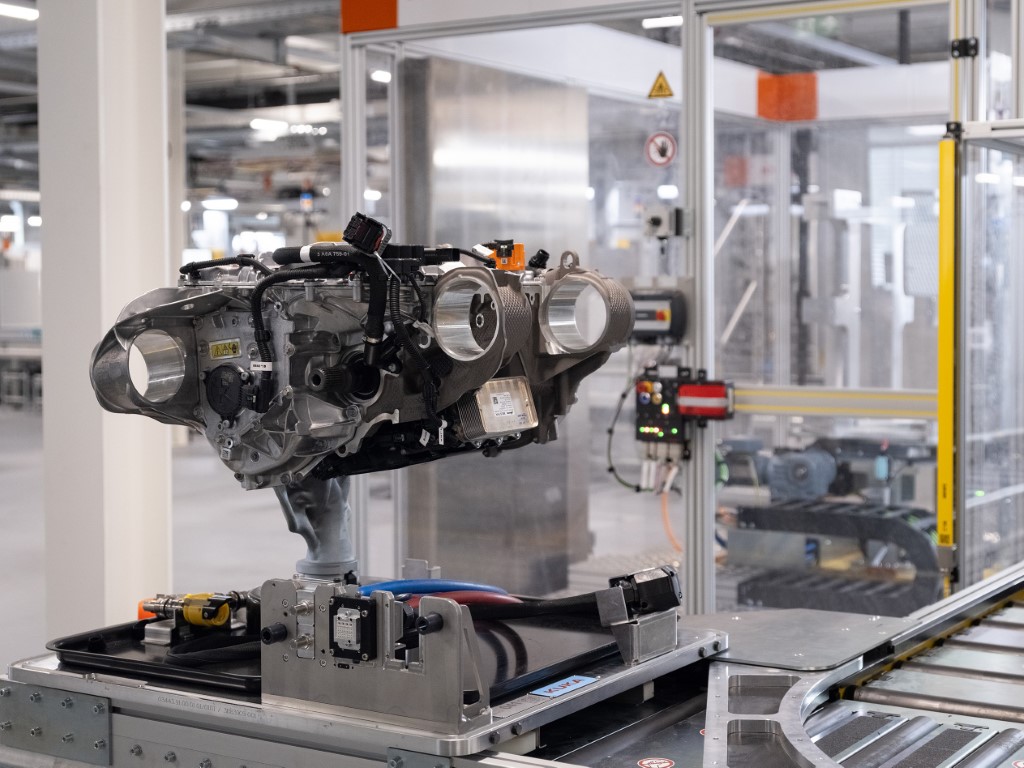

Rotor, stator, transmission and power converter – all core components of the innovative, highly integrated e-drive – will be manufactured at Plant Steyr.

The housing for the electric motor will be cast at Plant Landshut's aluminum foundry and further processed in Steyr.

The power converter will be produced in a new in-house clean-room environment, marking the Austrian engine manufacturer’s entry into the field of electrical motorering.

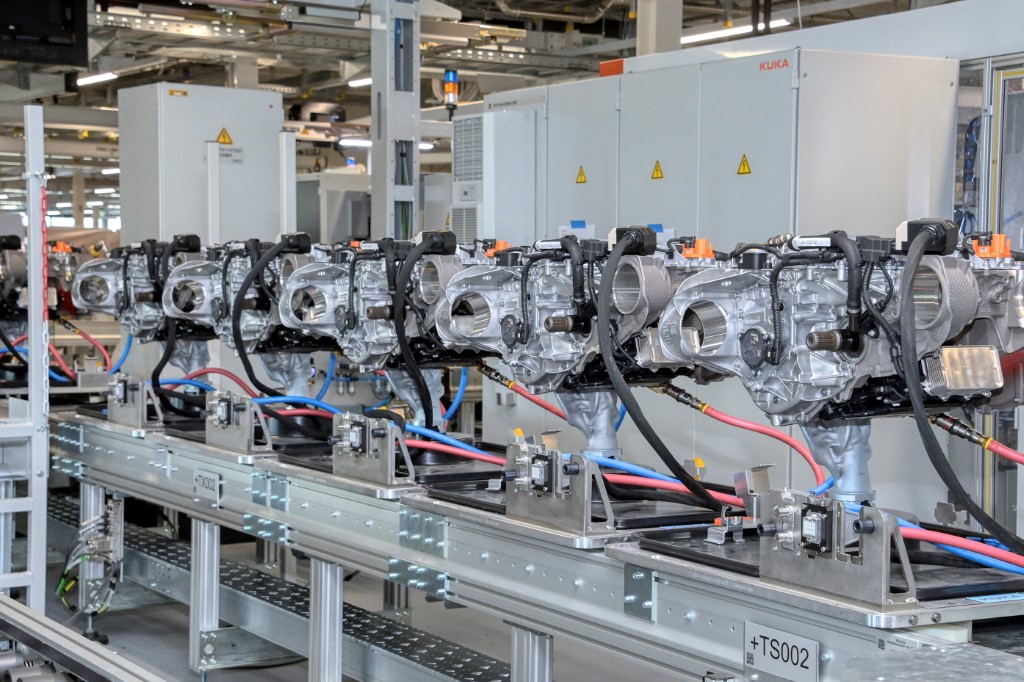

E-drive components from Steyr will be assembled on two new lines.

The overall production concept for the Gen6 e-drive follows the principle of a modular system, making it possible to produce different highly flexible electric drivetrain derivatives for the entire range of Neue Klasse models.

The modular concept generates positive economies of scale and cost savings in both development and production. It also improves the scalability of production volumes.

The modular approach keeps production, supply networks and procurement highly flexible.

Overall, the intelligent use of new technologies in the e-drive and systematic further development of existing systems produce remarkable results.

Comparing one of the future models of the Neue Klasse with a Gen5 xDrive model shows the improvements in the electric motor: “Energy loss is reduced by 40 percent, costs by 20 percent, and weight by 10 percent.

All this makes a significant contribution to the approximately 20-percent increase in overall vehicle efficiency”, explains BMW AG's SVP of global powertrain development Martin Kaufmann.

“The efficient design of the powertrain together with the high energy content of the high-voltage battery, enable a range of up to 800 km (WLTP) in the BMW iX3, the first model of the Neue Klasse.”