STUTTGART: Mercedes-Benz has unveiled the Tomorrow XX technology programme as a driver of innovation in support of the company’s sustainability objectives.

It leverages the same holistic, multi-disciplinary approach successfully demonstrated with Vision EQXX and Concept AMG GT XX.

Now, for the first time, an XX technology programme extends across the entire product portfolio.

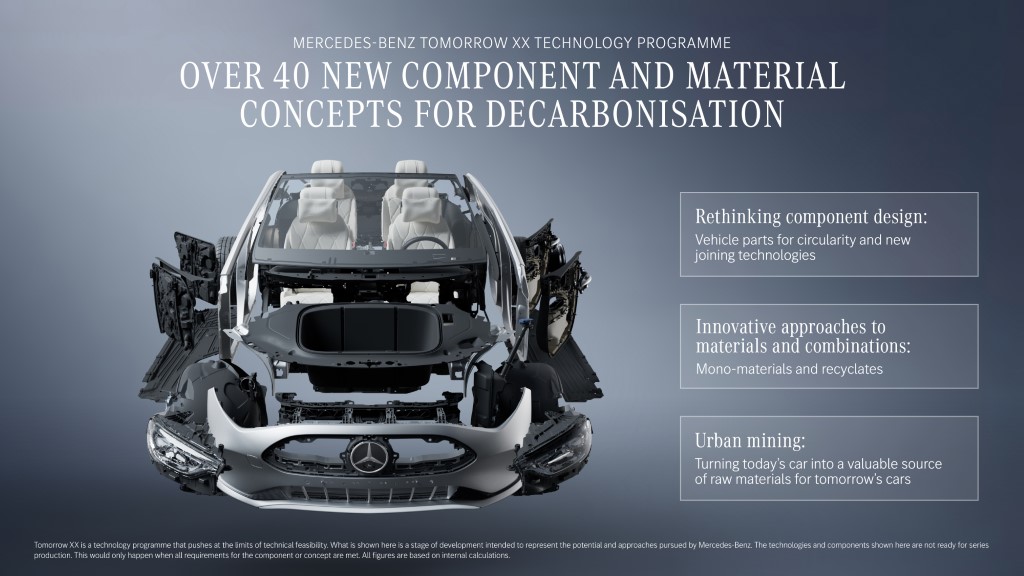

The Tomorrow XX programme focuses on decarbonisation, resource use and circularity from the start of the design phase to the end of a vehicle’s lifecycle.

In partnership with suppliers, institutions and start-ups, Mercedes-Benz is pushing the limits of what is technically achievable to develop new solutions and bring these to series production.

The exhibit that was unveiled recently showcased more than 40 components and materials that serve as examples of what is already being achieved or demonstrating enormous potential.

“There can be no doubt that the overriding goal for all our products is to excite our customers while decarbonising the automobile, driving down resource use and growing the circular economy,” said Mercedes-Benz Group AG management board member (integrity, governance and sustainability) Olaf Schick.

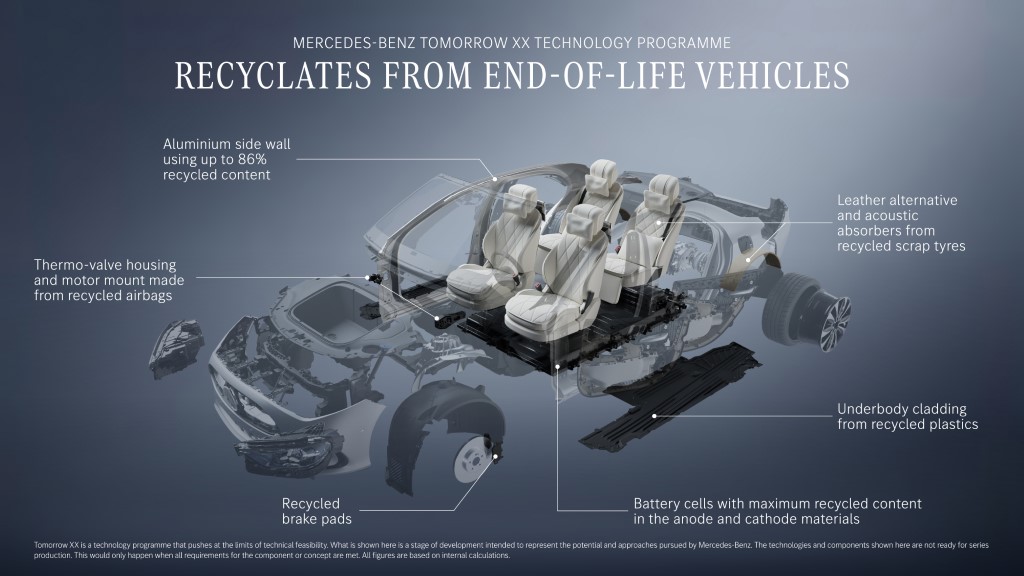

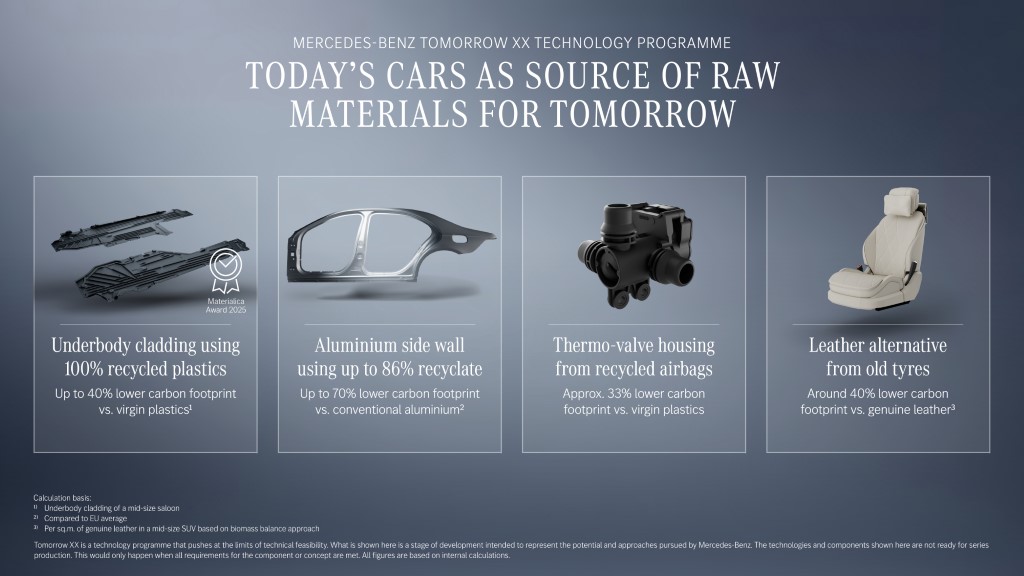

On average, a modern Mercedes-Benz vehicle contains 550 pounds of plastic.

Many of these components consist of mixed plastics, which can only be mechanically recycled to a limited extent and are therefore often thermally recycled.

Recovering these for use in high-quality products is usually not possible.

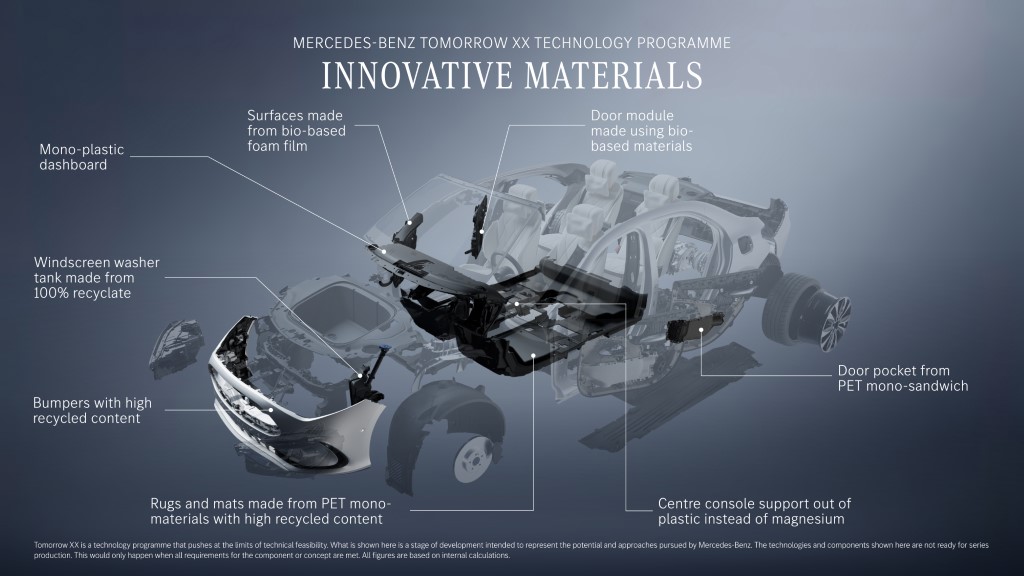

The Tomorrow XX technology programme focuses on accelerating the use of mono-materials, while also replacing primary resources with secondary materials.

Mercedes-Benz is working to change the design of highly complex components to make these quick and easy to disassemble into individual parts.

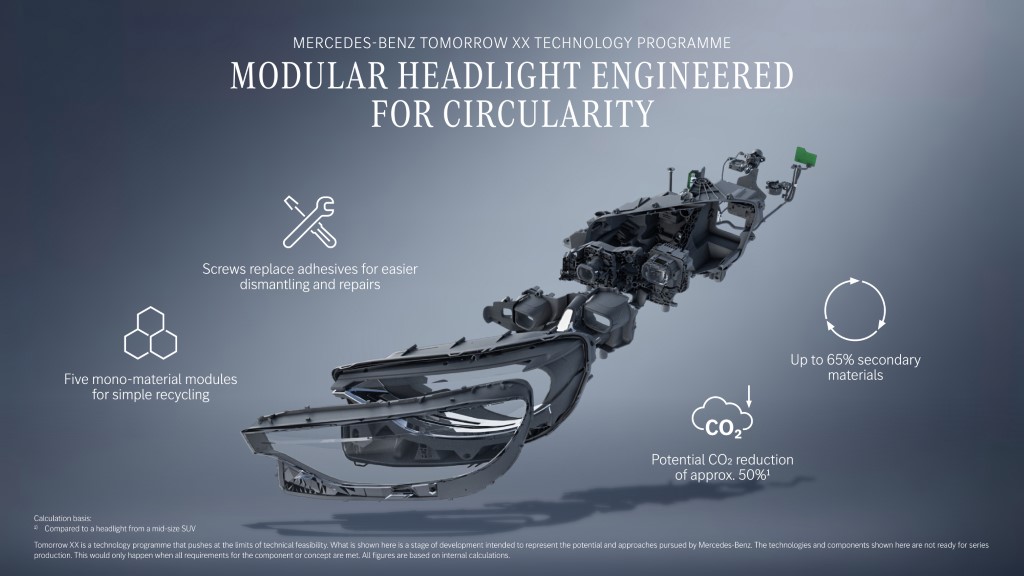

A promising Tomorrow XX research project is a recyclable headlight.

The various components such as the lens, cover trim and frame, housing and electronics are joined with fasteners rather than glue (today’s standard practice).

As a result, the headlight can be separated into individual components with ease and without damage.

This means individual components can be replaced, making a modern headlight repairable for the first time.

Following a stone chip, for instance, there is no need to replace the entire headlight, just the lens.

For customers, this could make repairs more efficient in future.

The longer service life of headlights could also help conserve resources and minimise carbon emissions.

The headlight concept is also designed to be better for recycling.

Individual modules are each made of only one material to ease sorting and to be highly efficient to recycle.

Looking to the future, this mono-material design should make it possible to use more recycled material and source a large part of this from old headlights.

The proportion of secondary materials could potentially be almost doubled compared to today’s headlights, while carbon emissions could be reduced by nearly 50 percent.

A similarly complex component are interior door panels, which consist of different parts joined by ultrasonic welding.

Mercedes-Benz has developed a new joining technology to better and more easily separate individual materials.

The adapted thermoplastic rivet is now easy to undo, allowing faster separation of individual components without damage.

Optimising dismantling in this way both simplifies repair and improves recyclability.

The new technology could potentially replace a large number of thermoplastic joints in vehicle interiors.