JAKARTA: The Chery Super Hybrid (CSH) hybrid battery has demonstrated exceptional durability and real-world safety during the Chinese automaker's second phase of its Global Safety Challenge – battery test campaign in Indonesia.

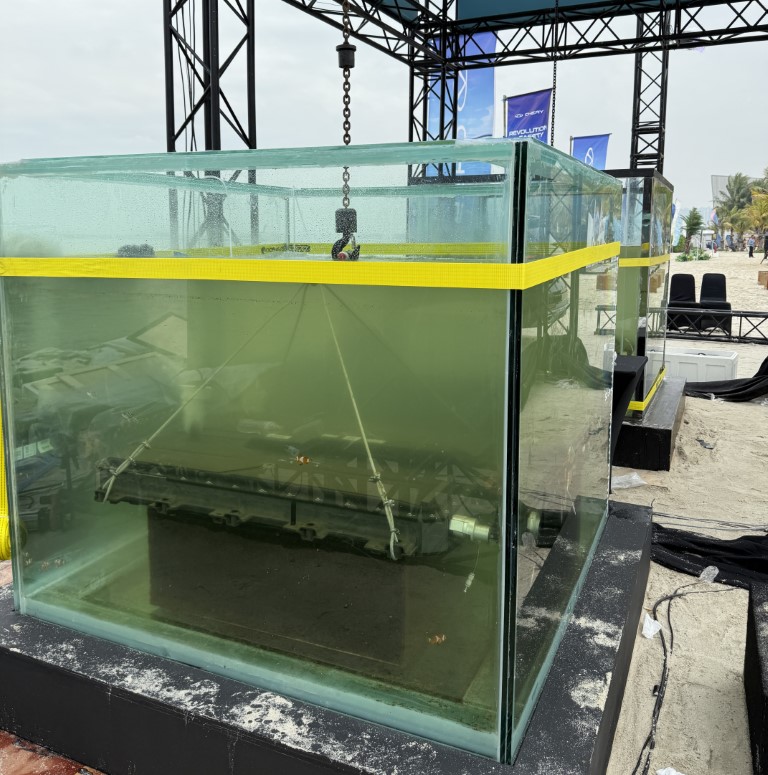

Two Chery CSH batteries were submerged in a one-metre-deep tank filled with seawater for more than 53 hours, simulating the corrosive and high-pressure conditions commonly found in flood-prone regions.

The test was conducted in front of local and international media and culminated in the battery being reinstalled into a Chery Tiggo 8 CSH sport utility vehicle (SUV) and driven down a steep ramp by Chery Sales Indonesia vice president Zeng Shuo, who was accompanied by Chery Sales Indonesia director Budi Darmawan Jantania - thus proving its operational safety even after prolonged seawater exposure.

“Through the ‘seawater immersion and real-world driving evaluation’, we have validated the battery’s seal durability against corrosive liquids, and comprehensively examined its insulation performance, structural integrity, and charge/discharge stability."

"These results confirm that Chery’s battery systems are built to remain robust even under the most extreme environmental conditions,” said Chery Sales Indonesia head of brand department

Rifkie Setiawan.

The battery test also goes far beyond standard waterproof benchmarks — seawater’s high conductivity and corrosive nature significantly accelerate material degradation compared to rainwater exposure.

In a statement, Chery Malaysia said the successful completion of this extreme test validates the CSH battery’s capability to operate safely in Southeast Asia’s harshest conditions, preventing risks such as short circuits, leakage, or fire.

The SUV uses an 18.3 kWh Lithium Iron Phosphate (LFP) battery, certified with IP68 waterproofing for resistance to water and dust.

It remains operational across an extreme temperature range from -35°C to 60°C and delivers up to 90km of pure EV (electric vehicle) range.

The battery also supports fast charging via CCS2, reaching from 30% to 80% in just 20 minutes.

Its Chainmail Battery Safety Structure, designed with 14 safety anchor points, boosts chassis strength by 7% and can withstand extrusion forces up to 200kN.

The protection system is reinforced by a multilayer insulation design—10 layers at the base, 15 on the sides, and 16 thermal layers.

This durability has already been proven in China through a series of extreme safety challenges, including spiral rollovers, dual collisions, a 7-vehicle stack test, 55kph intrusion test, 4.9-metre drop test, and 720-hour salt spray exposure.

Chery’s next stop in its Global Safety Challenge will be Mexico.

The Chery Tiggo 7 CSH will undergo a rigorous underbody scraping test in the country’s rugged highland terrain.

This will assess the battery pack’s protection in challenging road conditions and the system’s stability at high altitudes.

Chery plans to bring its Safety Challenge campaign to other key markets such as South Africa, and Brazil too.

Each stop will feature the durability of Chery’s electrified technology under different climate challenges.